Epoxy resin flooring services

Donnelly flooring is a leading epoxy flooring specialist in the resin flooring industry, and we have been installing flooring systems for over ten years. We have a vast knowledge of every flooring system from screeds to epoxy and even water based products.

Donnelly Flooring has over 15 years experience with concrete and concrete floors, so we know especially what is needed for each floor type to get the best possible outcome for your project.

We offer floor installations to work round our customers needs in order to have the least impact on your business, consistently working weekends and in normal business down time after hours.

Our experience with Customers and projects of all types means we can complete the perfect installation for your business.

Floor Preparation

Diamond Grinding

“Diamond Grinding” is a process we use in preparing concrete flooring for the application of epoxy resin flooring materials. It is used to clear the surface of any marks or stains and “key” the surface ready for the application of the epoxy resin primer.

The grinder discs are made using synthetic diamonds, and come in a variety of sizes to cater for fine (smaller size), and course (larger size) depending on the level of cleaning needed for the surface.

As the grinder is used, the concrete dust material is “sucked” away using an industrial scale vacuum, and afterwards the remaining material left on the floor is swept and cleared away.

Using this “diamond grinding” process we are able to clear away the most stubborn stains and marks, along with heavily marked areas that require a more rigorous and aggressive level of grinding.

Shot Blasting

“Shot Blasting” is a process that differs from “diamond grinding” in that the concrete surface is cleaned using steel pellets that are blasted at the floor and high speed and with great force. The pellets clean away dirt and markings, and the resulting dust generated is separated from the pellets so that the pellets can be recycled and re-used in the process.

An industrial scale vacuum is used to pull away the dust and pellets, and the machine also separates the pellets from the dust so they may be re-used. As the pellets are re-used they will eventually wear and turn to dust themselves so the process does use a continuing supply of pellets.

Shot Blasting vs Diamond Grinding

Whether we use “Shot Blasting” or “Diamond Grinding” to clean the surface, the aim is to clear the concrete floor as efficiently and effectively as possible so that the resin flooring material have the best possible surface to “key” in to.

Preparation is very important to ensure the quality of the base before applying the epoxy resin flooring. Without a good base the surface may not last as long as it should.

Depending on the scale of the work required on a project, we may use both processes to produce the best possible result for the preparation.

Application of a primer layer

On all of our projects, we carry out a vital middle step in the process which involves applying a primer resin layer to the floor. Application of this layer helps to seal the surface, and highlights any areas needing repair that were not obvious during the initial part of the preparation.

Once the repairs are completed, we will carry out a fine grinding of the surface in order to prepare it ready for application of the top coat of resin flooring material.

This additional step in the process helps key the surface for the final layer of resin, and allows us to ensure the finished surface is of the highest quality.

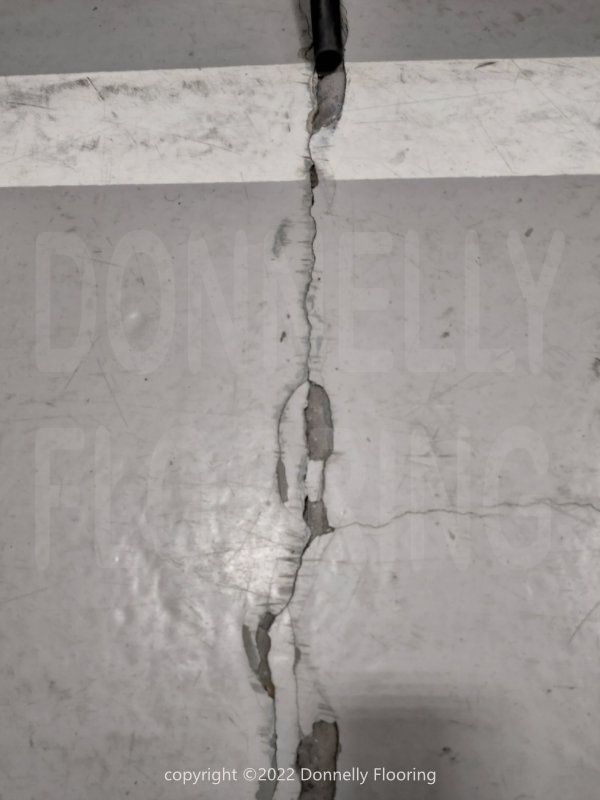

Concrete Repairs

On many of our projects, we find it is necessary to carry out repairs to the concrete surface prior to the application of the final epoxy resin flooring coating. Concrete surfaces do crack, so often a repair is needed to mend the surface and make it durable enough to withstand the heavy vehicles that will traverse the floor as it is in use.

Surface Cracks

Surface cracks are the most common issue needing repair on a concrete floor, and depending on the level of damage we encounter, we may use different techniques in the repair.

Cracks will vary in size and depth, and while some may be deep in places, others may not be so deep but are quite long and require more work to repair.

It is essential to repair and fill any cracks to prior to applying the final resin flooring surface. Some larger cracks may also represent a trip hazard, so it is important to repair these during any refurbishment to ensure there are no resulting injuries.

Expansion joints

Due to it’s rigid nature, concrete flooring will often have small gaps between larger areas of concrete to allow for expansion of the concrete as the temperature fluctuates. These gaps allow for the expansion and contraction of the concrete, and it is essential to repair any damaged gaps to make the joint as level as possible.

A badly repaired joint can lead to an uneven surface and in extreme cases could create a trip hazard.

Preventing water penetration under doors

Doorways and indeed walkways can often present a problem where preventing any water or liquid from penetrating under the door is needed. If there is any damage in the form of cracks or gaps this could allow liquids penetrating under the door and causing damage to whatever lies beyond.

It is therefore essential that any cracks and other damage is repaired prior to the application of the epoxy resin floor coating.

Resin Flooring

Resin flooring is used in a variety of commercial or industrial environments and due to it’s durability is especially suited to those environments where heavy traffic may be experienced. This is one reason why it is a popular choice for HGV Authorised Testing Facilities, motor industry vehicle workshops, warehouses and showrooms.

Benefits & advantages of Resin Flooring

Resin flooring provides a clean and aesthetically pleasing surface, and along with appropriate demarcation lines and zones can help to organise and separate larger areas into defined workspaces.

Resin flooring surfaces are also easy to clean, and the durable resin surface is quite resistant to a variety of cleaning compounds and machinery that is used by many businesses.

As the resin flooring is “poured” on to the floor in a “liquid-like” state, it is able to fit almost any shape and size of flooring space, and will fill in any awkward gaps or shapes.

But most of all, resin flooring provides a very durable surface that will stand up to the rigours of many industrial environments.

Where to use resin flooring

Resin flooring can be used in many commercial and industrial environments. Almost anywhere there is a need to provide a durable, long lasting, and aesthetically pleasing surface.

This makes it ideal for Garage workshops and showrooms, HGV workshops and testing facilities, vehicle showrooms, and warehouses. Being very durable, it is very well suited for high or heavy traffic areas.

Anti Slip Surfaces

In any industrial or commercial environment, safety of workers and the public is always a concern. It is important that businesses recognise the important of safety and employ processes to ensure that flooring surfaces used my employees and the public a safe and comply with the recommendations set out by the HSE.

Why Have Anti Slip surfaces

The importance of anti-slip surfaces should not be under estimated. Slips and trips are the most common cause of serious injuries at work, and having an anti slip surface applied to a resin floor can help reduce the risks.

The HSE has produced a setup of recommendations for measuring and assessing the slip resistance of commercial and industrial floor surfaces, and there are numerous companies that will assist in testing existing and new flooring surfaces to ensure they measure up.

Benefits & advantages of anti slip surfaces

There is no doubt that having an anti slip surface can help to reduce the risk of slips in the work environment, and when combined with anti slip materials, resin flooring is ideal for any environment where safety is a concern.

Anti slip surfaces can help reduce the risk of slips and trips and work, and may also help to avoid any costly legal actions involving injuries to workers or the public.

You may be interested in these projects

Visit our Portfolio/Projects page to view more epoxy resin flooring projects completed successfully by Donnelly Flooring

3a Woodridings

Lichfield

Staffordshire, WS13 7HR

United Kingdom

2nd Floor

College House

17 King Edward Road

Ruislip

London, HA4 7AE

United Kingdom