B&Q Warehouse

Donnelly Flooring was trusted by B&Q to carry out resurfacing and repair work to flooring in one of it’s busy warehouses. A change in the layout of some displays meant that the flooring surface where displays had been needed repair and new resin flooring. In addition the area along several display isles was given a new epoxy resin flooring surface.

Where displays had moved the surface below was partly bare concrete where the existing flooring surface had previously run up to the displays. The areas left behind after the move of the displays represented a trip hazard, so it was necessary to install the new resin flooring and make it level with the existing flooring surface.

As the warehouse operates 7 days per week, the work was carried out during hours when the store was closed to the public in order to ensure there was no disruption to the opening hours of the business.

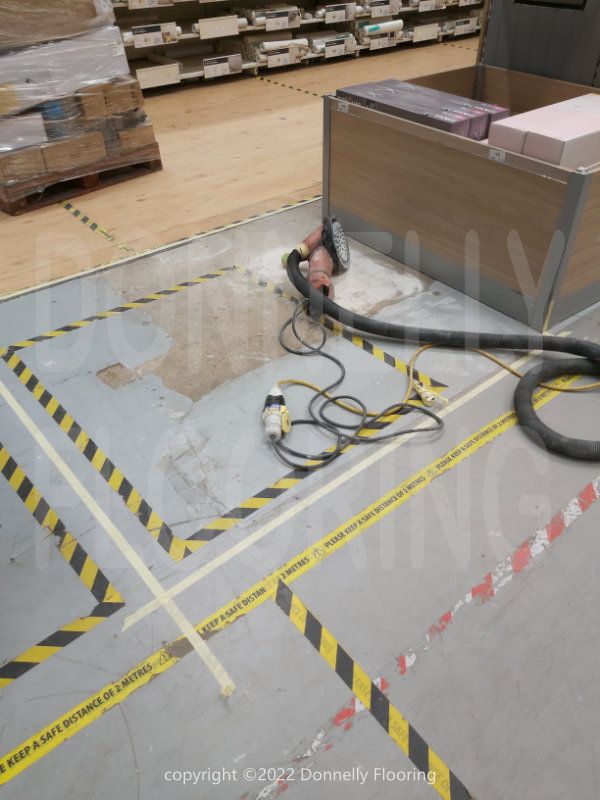

Preparation work for epoxy resin flooring

Good preparation is an essential part of the refurbishment process. In the areas where displays had been, the process starts by cleaning the floor and removing all unwanted material such as dirt and grime, and any old paintwork.

We also needed to prepare the areas in several display isles, and a larger section in one part of the warehouse.

We used a “Diamond Grinding” process to prepare the floor and to help key the concrete surface ready for the next stage.

Epoxy resin flooring – application of the top coat

After completion of the preparation work, the final part of the process is to apply the resin flooring top coat to the isles and display areas. The new surface provides a cleaner and more presentable area for the visitors to the store.

As is our standard we provide advice on floor maintenance, including which solutions to use and how to keep the floor looking as good as new.

At the outset, a major concern was the trip hazard left by the move of several displays, so it was important the finished surface on those areas was seamlessly integrated in to the existing flooring surface. To help contribute to the safety of the warehouse staff and customers, an anti-slip surface was also added.

Other resin flooring projects

3a Woodridings

Lichfield

Staffordshire, WS13 7HR

United Kingdom

2nd Floor

College House

17 King Edward Road

Ruislip

London, HA4 7AE

United Kingdom